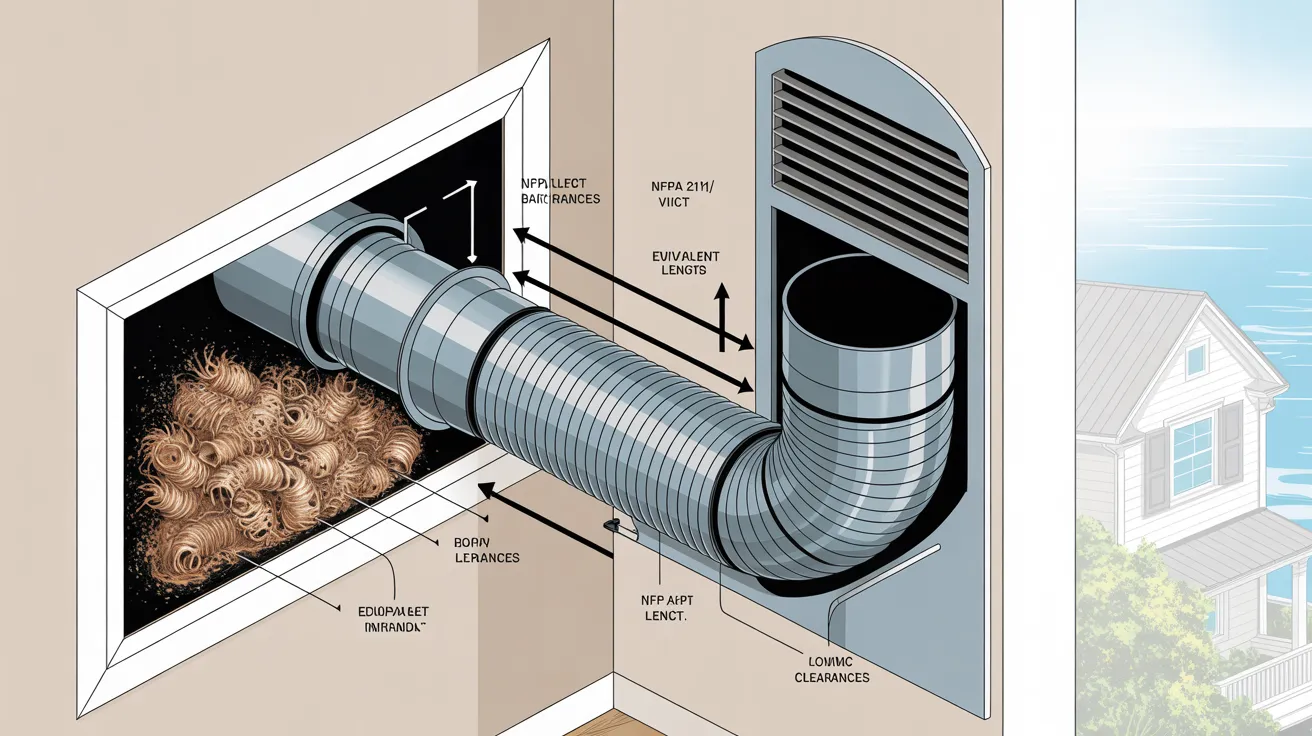

Need expert West Palm Beach dryer vent cleaning specialists? We ensure reliable, code‑compliant airflow by implementing HEPA‑contained extraction, rotary brushing, and instrumented verification. You'll see faster drying times, minimized fire risk, and enhanced indoor air quality in our coastal humidity. We comprehensively evaluate run length, elbows, materials, and termination according to NFPA 211/IMC, then log pre/post CFM, static pressure, temperature rise, and photos. We correct crushed flex, properly seal joints with UL foil tape, and check damper function. See how we deliver measurable improvements next.

Core Insights

- Professional dryer vent experts serving West Palm Beach, optimizing safety from fires, indoor air quality, and power efficiency per NFPA 211 and manufacturer specs.

- Comprehensive cleaning: featuring HEPA negative-pressure capture, rotary brushing, termination hood cleaning, and UL-2158A certified repairs and sealing.

- Complete system analysis with airflow measurements, static pressure testing, temperature differential checks, and amperage monitoring; complete with before and after photos and detailed test results.

- Immediate action when you notice warning signs: long drying times, very warm appliance housings, unpleasant smells, poor exterior airflow, or activated thermal protection devices.

- Coastal-focused solutions to combat moisture-related issues and corrosion concerns; providing complete service packages for houses, homeowner associations, and commercial properties.

Understanding Dryer Vent Cleaning Significance in West Palm Beach

Because lint collection is a primary cause of residential fires, periodic dryer vent cleaning in West Palm Beach is a critical safety measure that decreases fire hazard, improves airflow, and maintains equipment according to manufacturer and NFPA 211/CSA C22.1 standards. You'll also protect wiring, terminations, and junction ducts from heat stress and excessive pressure. By removing obstructions, you recover design static pressure, optimize exhaust flow, and lower cycle times, boosting energy efficiency and prolonging motor life.

In regions with coastal and high-humidity climates, maintaining appropriate humidity levels in your laundry area is crucial. Clean vents efficiently remove moisture-laden air, helping prevent mold formation, condensation issues, and ductwork deterioration. Professional maintenance confirms correct duct installation requirements, including appropriate metal duct surfaces, properly sealed joints, and proper termination clearances, while validating proper utility connections and damper operation. You'll achieve safe, code-compliant operation throughout the year.

Warning Signs Your Dryer Vent Requires Immediate Service

When your dryer displays thermal stress, ventilation problems, or utility abnormalities, consider these red flags that need immediate attention. If the unit's cabinet or door feels unusually hot, the exhaust duct could be obstructed. Prolonged drying times suggest diminished air movement and pressure concerns within the ventilation system. Unpleasant mustiness suggests water retention due to inadequate ventilation. Lint accumulation around the outdoor hood, a malfunctioning backdraft damper, or compromised duct work all point to ventilation problems.

Watch for reduced exhaust output at the outlet, a tripped thermal fuse, or repeated cycling on the high‑limit thermostat. Heat discoloration, rattling ducts, or loose elbows indicate inadequate support or fasteners. When you observe the gas burner short‑cycling or find erratic amperage, power off the unit and schedule a vent checkup.

Key Benefits: Fire Safety and Air Quality Standards

Although a dryer appears to be a common household fixture, the venting system represents a major fire risk if lint accumulates or air movement decreases. You lower fire dangers by keeping duct sizes at specification, fitting metal couplings, and maintaining code-compliant vent endings. Adequate ventilation decreases temperature, better prevents smoke issues, and decreases dangerous check here lint accumulation. Additionally, you protect residents from CO gas intrusion when gas dryers have unrestricted airflow and all seals remain intact.

Clean ducts improve interior air quality. Optimal air filtration at the appliance and clear exhaust facilitate allergen reduction by filtering out lint, dander, and particulates instead of recirculating them. Managed exhaust optimizes humidity control, reducing dampness problems and wall cavity condensation. Shorter cycles lead to lower thermal stress, prolonging fabric lifespan. Complying with NFPA 211/54 clearances and UL-listed components ensures safety and efficiency.

Our Professional Dryer Vent Cleaning Procedure

You start with a thorough assessment and regulatory inspection to locate blockages, damaged ducts, and termination issues. Next, we conduct controlled lint and debris removal using proper agitation and negative-pressure collection to avoid spreading. We complete the process by verifying performance through calibrated airflow measurements and document that exhaust performance meets manufacturer and local code specifications.

Evaluation and Inspection

Before commencing any maintenance, our technicians carry out a thorough inspection and regulatory compliance check to determine baseline conditions and pinpoint potential hazards. We start with a visual inspection of the connection hose, vent pathway, termination hood, and spacing to confirm UL-listed components, appropriate routing, and secure connections. We validate duct material, length, and equivalent elbows according to manufacturer specifications and Florida Building Code requirements.

We evaluate airflow, static pressure, and backdraft damper operation to flag potential restrictions or improper venting. We perform moisture analysis at the lint trap, connection points, and exterior cap to spot condensation issues or damaged ductwork. We examine combustion air intake, exhaust spacing, and electrical bonding. You'll get documented results, prioritized safety concerns, and recommended fixes prior to additional work.

Cleaning Lint and Debris

With baseline conditions documented, we advance directly into lint and debris removal using techniques tailored to your dryer vent's characteristics. We initially isolate power, safeguard the appliance, and set up high-efficiency HEPA vacuum to maintain negative pressure. You'll see us deploy mechanical brush systems or air-whip agitation sized to the duct diameter, safely dislodging compacted dryer lint and vent debris without stressing joints or flexible components.

We start from termination to the appliance, meticulously clearing connectors, seams, and elbows, then vacuuming with antistatic equipment to prevent debris re-entrainment. We package and record the extracted debris for your documentation. We service the termination hood, damper, and bird screen, ensuring proper operation. Finally, we check and re-seat the clamps, confirm screw tightness, and replace any noncompliant foil or plastic junctions with components meeting UL-2158A standards.

Airflow Testing Verification

Verify functionality through instrumented airflow measurement. Following debris removal, you should confirm system efficiency utilizing calibrated diagnostic instruments including anemometers, manometers, and hygrometers. Set baseline measurements at the exterior outlet with the dryer connected and running on a timed cycle. Log duct static pressure, velocity, and volumetric flow. Compare these measurements against OEM specifications and ACCA/ASHRAE guidelines to ensure safe operation.

Carry out pressure analysis along critical areas including inline fittings, exterior hood, appliance collar, and connector hose. Detect unusual pressure reductions that suggest residual blockage, crushed flex, or backdraft damper issues. Confirm that air movement properly clears lint while staying within code limits for flex duct.

Record ambient humidity and temperature readings to help understand test outcomes. Should targets fall short, specify appropriate corrective measures. Conclude by attaching performance results to maintenance files for regulatory compliance and later use.

Professional Tools and Techniques We Employ

While each home is distinct, we utilize a standardized equipment to completely clean vents and adhere to code. You receive a detailed process that prioritizes fire safety and optimal air circulation. We commence with mechanical assessment to map the entire duct path, verify elbows, and locate constrictions without disturbing finishes. Subsequently, we use thermal imaging to detect hidden heat irregularities indicating lint buildup, crushed flex, or loose joints.

Our team employs rotary-brush shafts sized according to duct diameter, then collect debris with HEPA-filtered negative pressure avoiding indoor re-entrainment. Where code permits, we implement flexible cleaning heads for delicate areas and nylon extensions for solid metal sections. We measure motor amperage, inspect backdraft damper functionality, and seal joints using UL-listed foil tape, rather than standard duct tape, delivering long-lasting, code-compliant outcomes.

Services for Homes, Condos, and Businesses

We provide specialized residential solutions that match equipment specifications and duct parameters while following NFPA 211 and manufacturer standards. For multi-unit dwellings, we manage access arrangements, document results, and align with HOA bylaws and local fire code to maintain shared shafts and booster fans compliant. Companies receive commercial-grade maintenance programs with scheduled cleaning, airflow testing, and detailed reports to fulfill OSHA expectations and AHJ inspections.

Personalized Home Solutions

Engineered exclusively for diverse living spaces, our tailored residential dryer vent systems handle the specific code requirements, airflow considerations, and maintenance requirements common to various residential properties including houses, condominiums, and townhouses. We initiate with a comprehensive assessment following NFPA 211 and IRC standards, measuring duct length, elbow count, termination type, and material. Then, we remove lint and obstructions using specialized rotary brushing and HEPA-contained negative pressure to reestablish optimal airflow and pressure specifications.

We maximize energy efficiency by checking vent run geometry, fixing crushed flex, sealing joints with UL-listed foil tape, and adjusting proper backdraft damper tension. You'll receive documentation: detailed reports showing before/after airflow, amperage, temperature differences, and photographic evidence. Given West Palm Beach humidity, we advise seasonal scheduling prior to peak dryer use, guaranteeing safe operation, faster dry times, and reduced wear.

Condominium Association Guidelines

Given that the risk concentration in multi-unit properties, our condominium compliance service coordinates dryer vent operations with key safety codes like NFPA 211, National Electric Code, and IRC/IMC, plus your governing documents and coverage mandates. We implement consistent workflow, access guidelines, and reporting to satisfy association requirements while minimizing resident impact.

We start with compliance audits of ventilation shafts and internal duct systems, checking material composition, routing, termination points, backdraft dampers, and makeup air. We'll deliver safety-prioritized documentation, visual documentation, and corrective action plans. Our experts clear obstructions, replace non-compliant flexible materials, seal joints with UL‑listed materials, and determine service frequency based on occupancy and lint load.

We record and timestamp all reports, track and monitor unit participation, and provide detailed proof-of-service documentation for insurers, boards, and fire inspectors.

Commercial Maintenance Services

While fire risk escalates with lint buildup and runtime, our commercial-grade maintenance services implement dryer vent maintenance for houses, apartments, and commercial spaces under the same code-compliant framework. You'll benefit from NFPA 211/54-aligned inspections, airflow measurements, and recorded cleaning intervals aligned with usage patterns and occupancy.

We arrange preventive maintenance contracts that specify scope, frequency, and response SLAs, protecting you from system failures and regulatory issues. Our dedicated technicians verify appropriate ducting components, termination, and damper performance, then measure system pressure and air speed to validate system efficiency. We clear obstructions, reseal joints, optimize system distribution, and upgrade compromised flexible ducts with metal ducting where required.

You'll get chronological reports, initial and final readings, and remediation documentation-vital proof for insurance requirements, Authority Having Jurisdiction reviews, and administrative assessments.

Scheduling Your Dryer Vent Maintenance: Timing Guidelines

It's recommended to arrange professional dryer vent cleaning at least once every 12 months, or more frequently if your dryer sees heavy use (multiple loads daily), your vent ducting is extensive, or you notice red flags like extended drying times, excessive lint, or the smell of burning. In West Palm Beach's humid climate, lint can become damp, adhere to duct walls, and impede ventilation faster, so be sure to stick to yearly service schedules. Adjust scheduling to usage levels: quarterly for salons, spas, or large families; semiannual for typical homes; annual for standard residential use.

Set up routine inspection alerts at the beginning of seasonal weather changes to evaluate ventilation efficiency, termination flapper functionality, and duct system reliability. Be sure to check exterior clearance requirements, bird guard status, and verify that ventilation conforms to recommended CFM requirements and municipal requirements.

Complete Pricing Information and Inclusions

Once your service interval is established, you'll understand exactly what you're paying for. You receive detailed quotes before any work begins, with parameters based on vent length, wall or roof exit points, and code-access constraints. We detail automated cleaning methods, HEPA-filtered removal, ventilation assessment, airflow measurement (pre/post CFM), and termination cap cleaning. If needed, we document bird barrier replacement and approved connector modifications.

Choose flat rate pricing for basic single-run setups, or choose service packages combining airflow balancing, cleaning, and lint alarm setup. We document all findings with photos, static pressure readings, and NFPA 211/IMC compliance notes. Our itemized invoices detail labor, materials, access fees, and any roof-safety surcharge. No hidden costs - additional work (rerouting, repairs, or remediation) demands your written authorization prior to starting.

Real Customer Stories and Local Testimonials

As performance trumps promises, our customers report concrete results: improved drying efficiency, documented CFM gains, and post-service pressure readings meeting code requirements. In Customer testimonials, you'll see measured results: 30-50% faster cycles, fans restored to factory specifications, and lint loads reduced to safe thresholds. You receive NFPA 211-aligned methods, UL-approved materials, and documented airflow improvements.

Local milestones feature apartment complexes in West Palm Beach clearing HOA safety audits after remediation of compromised flex runs and improper terminations. Home inspectors report reduced dryer-fire hazards where we've resolved long-run friction losses and restored backdraft damper function. You'll receive before/after meter readings, documentation, and maintenance intervals. This transparency helps you manage filtration updates, monitor energy use, and ensure code compliance.

Popular Questions

Do Your Technicians Have Licenses, Insurance, and Background Checks?

Yes. Our team includes certified technicians who follow state and local codes, maintain current certifications, and adhere to manufacturer specifications. We carry full liability and workers' compensation insurance for your security. We conduct thorough background checks and continuous safety training, encompassing lockout/tagout, confined space awareness, and NFPA 211/IMC compliance. We record procedures, confirm clearances, and evaluate airflow and termination integrity. You can expect transparent reporting, chain-of-custody for keys, and visually documented results.

Do You Provide Emergency and Same-Day Dryer Vent Solutions?

Absolutely, we offer emergency and same-day dryer vent maintenance. We give priority to hazardous situations, blocked vents, and excessive heat problems with urgent appointments and same-day response. We deliver a NFPA 211/IRC-compliant inspection, performance checks, and debris clearing to recommended guidelines. We verify system infrastructure, correct vent exits, and spacing requirements, and report observations. We'll provide comprehensive reporting, photos, and maintenance advice, with workmanship warrantied and follow-up verification.

Are You Able to Service High or Hard-To-Access Exhaust Vents?

Absolutely, we maintain elevated and challenging ventilation endpoints. You work with technicians trained for rooftop access, fall protection, and confined-space practices. We utilize OSHA-compliant safety equipment and secure anchoring systems. We inspect termination caps, backdraft dampers, bird guards, and distances. We use rotary brushing, HEPA vacuums, and camera inspections to guarantee full airflow. You'll get detailed compliance records, imaging, and performance data. As required, we replace damaged caps and secure penetrations to manufacturer specs.

Does Dryer Cleaning Impact the Manufacturer's Warranty?

Professional dryer cleaning won't invalidate your manufacturer's warranty. For instance: when you schedule yearly vent maintenance, the technician removes lint buildup, restores proper airflow, ensures normal operating temperatures, and documents the service according to code. Such records strengthen warranty coverage by showing responsible maintenance practices. Always work with certified professionals who follow NFPA 211 guidelines and manufacturer protocols, don't allow improper dismantling, and ensure detailed documentation with photos and receipts. If existing damage is found, technicians will document it before servicing to protect your warranty coverage.

Are Before-And-After Airflow and Lint Volume Reports Available?

Yes. You'll get detailed airflow measurements and a detailed lint evaluation after service. We document pre- and post-cleaning airflow rates (CFM) using a calibrated anemometer and document static pressure changes. When examining lint, we quantify volume and weight, identify combustible buildup, and photograph findings. Documentation covers vent path conditions, code-compliance observations, and safety recommendations. You'll receive detailed, documented improvement data to assist with maintenance planning and documentation for insurance and property management.

To Sum Up

Safety, efficiency, and code compliance are priorities you value - and so do we. Dryer lint is highly combustible; the U.S. Fire Administration reports nearly 2,900 dryer fires annually, with most starting in clogged vents. Imagine a vent packed like a felt blanket restricting airflow and causing elements to overheat. Proper servicing can minimize fire dangers, enhance IAQ, and meet manufacturer and NFPA 211 standards. Remember to schedule periodic service, log findings, and confirm airflow and termination. These steps will protect your property, decrease energy consumption, and ensure your system operates within specifications.